The Importance of Forklift Safety

This is a subtitle for your new post

Understanding the Factors That Compromise Forklift Safety

Forklifts are indispensable tools in various industries, facilitating the efficient movement of goods and

materials. However, despite their utility, forklifts pose inherent risks, particularly when it comes to

stability. Understanding the factors that compromise forklift stability is crucial for preventing accidents

and ensuring the safety of operators and bystanders alike.

How to Handle Load and Distribution when using a Forklift?

Load Capacity and Center of Gravity

One of the primary factors affecting stability is load handling and distribution. Exceeding the forklift's rated load capacity or improperly positioning loads can shift the centre of gravity, destabilisingthe vehicle. Operators must adhere to load capacity limits specified by the manufacturer and ensurethat loads are evenly distributed and secured to prevent imbalance.

Shifting Loads

Dynamic shifts in load distribution during lifting, lowering, or travelling can compromise forklift stability.Sudden movements or impacts can cause loads to shift unexpectedly, altering the centre of gravityand increasing the risk of tip-overs. Proper stacking techniques, securement methods, and cautiousmanoeuvring are essential for minimising the potential for load shifts and maintaining stability.What should the Operating Conditions and Environment be when Handling a Forklift?

Surface Conditions

Surface conditions play a significant role in forklift stability. Uneven or slippery surfaces, such as wetfloors, loose debris, or icy patches, can affect traction and manoeuvrability, increasing the likelihood ofskidding or tipping over. Operators should exercise caution when operating forklifts in challengingterrain or adverse weather conditions, adjusting their speed and technique accordingly to maintain

stability.

Slopes and Inclines

Navigating slopes and inclines presents unique challenges for forklift stability. Ascent and descentalter the distribution of weight and traction, potentially causing the forklift to tilt or lose control.Operators must approach slopes at a controlled speed, maintain a forward-leaning position, and avoidsudden stops or reversals to minimise the risk of tip-overs.How Should An Forklift Operator Behave and Train?

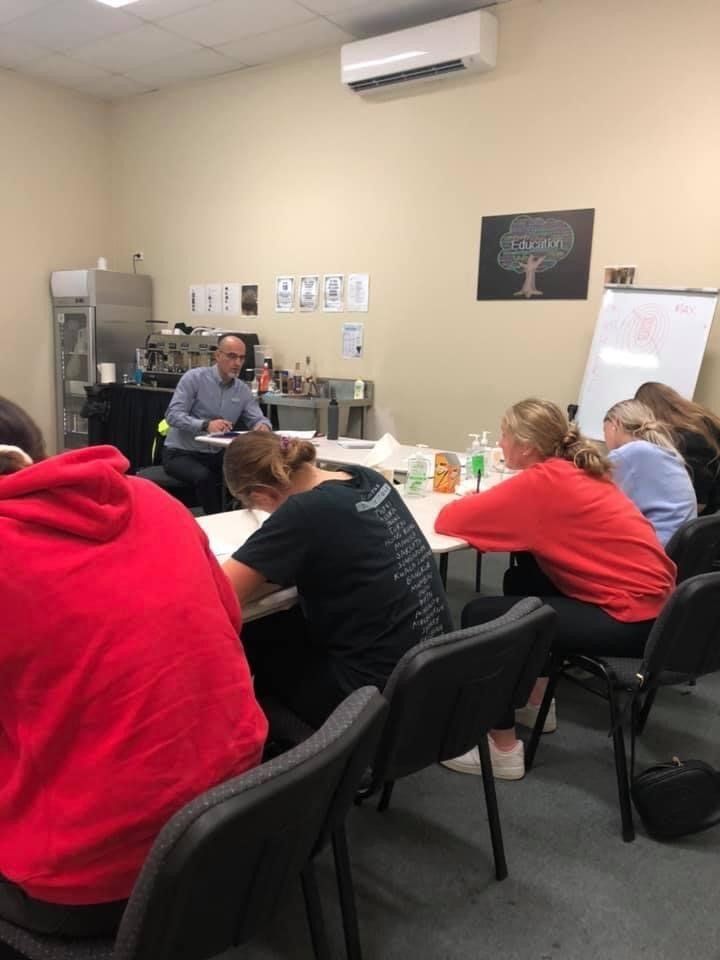

Operator Training and Experience

The proficiency and attentiveness of forklift operators significantly influence stability and safety.Proper training programs, including theoretical instruction and practical exercises, equip operatorswith the knowledge and skills to operate forklifts safely. Experienced operators understand theimportance of load handling techniques, situational awareness, and adherence to safety protocols,minimising the likelihood of stability-related incidents.

Unsafe Practices

Unsafe behaviours and practices compromise forklift stability and pose serious risks in the workplace.Examples include excessive speeding, abrupt manoeuvres, unauthorised modifications to the forklift,and failure to use seat belts or other safety restraints. Employers must prioritise safety training andenforcement of safety policies to mitigate the potential for accidents resulting from operatornegligence.

What is the Correct Forklift Design and Maintenance?

Equipment Condition

The condition of forklifts directly impacts stability and operational safety. Regular maintenance,inspections, and repairs are essential for identifying and addressing mechanical issues that couldcompromise stability, such as worn tires, faulty brakes, hydraulic leaks, or steering malfunctions.Employers should implement proactive maintenance programs to ensure that forklifts remain inoptimal working condition.

Design Features

Forklift manufacturers incorporate various design features to enhance stability and safety. These mayinclude wide wheelbases, low centres of gravity, tilt indicators, stability control systems, and operator restraint systems. Employers should invest in forklifts equipped with advanced afety features andensure that operators are trained to utilise these features effectively to minimise stability risks.What are the Expected External Factors and Hazards Of Forklift Usage?

Pedestrian Traffic

The presence of pedestrians in the vicinity of forklift operations poses a significant safety risk.Collisions between forklifts and pedestrians can occur due to limited visibility, distracted operators, orpedestrians entering restricted areas. Employers should implement traffic management strategies,such as designated pedestrian walkways, barriers, signage, and audible warning devices, to mitigatethe risk of accidents.

Congested Workspaces

Congested or confined workspaces increase the likelihood of collisions and obstacles thatcompromise forklift stability. Narrow aisles, cluttered storage areas, and obstructed pathways restrictmanoeuvrability and visibility, posing challenges for safe forklift operation. Employers should optimiseworkspace layout, implement traffic control measures, and establish clear communication protocols tominimise congestion-related hazards.

What Are The Appropriate Risk Mitigation Strategies and Practices for Forklift Operation?

Comprehensive Training Programs

Investing in comprehensive training programs is essential for equipping operators with the knowledgeand skills to navigate various stability-related challenges. Training should cover load handlingtechniques, hazard recognition, emergency procedures, and safe operating practices tailored tospecific workplace environments.

Regular Equipment Inspections

Routine inspections and maintenance are critical for identifying and addressing potential mechanicalissues that compromise forklift stability. Employers should establish inspection protocols, conduct pre-shift inspections, and promptly address any defects or deficiencies to ensure the continued safeoperation of forklifts.

Environmental Monitoring

Monitoring environmental conditions, such as surface conditions, weather forecasts, and terraincharacteristics, allows operators to assess potential stability risks proactively. Implementingprocedures for assessing environmental hazards and adapting operating practices accordingly helpsminimise the impact of external factors on forklift stability.

Promoting a Safety Culture

Fostering a safety-conscious culture is essential for promoting awareness, accountability, andadherence to safety protocols among all stakeholders. Employers should encourage opencommunication, provide ongoing safety training and reinforcement, and recognize and reward safebehaviours to cultivate a workplace environment where safety is prioritised.

Forklift stability is influenced by a myriad of factors spanning load handling, operating conditions,operator behaviour, equipment design, external hazards, and risk mitigation strategies. Byunderstanding these factors and implementing proactive measures to address them, employers can enhance forklift safety, mitigate stability-related risks, and create a safer working environment for all. Prioritising comprehensive training, equipment maintenance, environmental monitoring, and a safety-focused culture is paramount for minimising accidents and ensuring the efficient and secure operation of forklifts in diverse workplace settings. Remember, vigilance and proactive risk management are essential for safeguarding against stability-related incidents and protecting the well-being of operators

and bystanders alike.

What are the Precautions to Maintain Forklift Stability?

Forklifts are indispensable tools in warehouses, construction sites, and industrial facilities, facilitating the movement of heavy loads with efficiency and precision. However, ensuring the stability of forklifts is paramount to prevent accidents and ensure the safety of operators, bystanders, and valuable assets.

What are the Forklift Load Handling Precautions?

Adhere to Forklift Load Capacity Limits

One of the fundamental precautions for maintaining forklift stability is adhering to load capacity limits specified by the manufacturer. Overloading the forklift can shift the centre of gravity, increasing the risk of tip-overs. Operators should be trained to identify load capacity ratings and ensure that loads are within the safe operating limits.

Secure and Distribute Forklift Loads Evenly

Proper load securement and distribution are essential for maintaining stability during lifting, lowering, and transporting operations. Operators should use appropriate lifting attachments, pallets, and straps to secure loads and prevent shifting. Distributing loads evenly across the forks helps maintain a stable centre of gravity and reduces the risk of imbalance.

What Are The Operating Precautions When Using a Forklift?

Drive at a Controlled Speed

Excessive speed is a common contributor to forklift accidents, particularly when navigating corners, ramps, or congested areas. Operators should adhere to posted speed limits and adjust their speed based on the operating conditions, terrain, and visibility. Driving at a controlled speed enhances stability and allows operators to react quickly to potential hazards.

Avoid Sudden Stops and Sharp Turns

Abrupt manoeuvres such as sudden stops or sharp turns can destabilise the forklift and increase the risk of tip-overs. Operators should anticipate stops and turns, allowing for gradual deceleration and smooth steering movements. Maintaining a steady pace and avoiding sudden changes in direction helps preserve stability and control.

What Are The Environmental Precautions When Driving a Forklift?

Assess Surface Conditions

Surface conditions play a significant role in forklift stability, particularly in outdoor environments or areas prone to moisture or debris. Operators should regularly assess surface conditions for hazards such as wet floors, oil spills, loose gravel, or uneven terrain. Avoiding slippery or unstable surfaces reduces the risk of skidding or loss of traction.

Navigate Slopes and Ramps with Caution

Ascending or descending slopes and ramps requires careful attention to maintain stability and control. Operators should approach slopes at a controlled speed, keeping the load positioned uphill whenever possible. Avoiding sudden acceleration or braking on slopes minimises the risk of tip-overs and ensures safe traversal of inclines.

What Are The Forklift Equipment Maintenance Precautions?

Conduct Regular Forklift Inspections

Routine inspections are essential for identifying and addressing mechanical issues that could compromise forklift stability. Operators should conduct pre-shift inspections to check for signs of wear, damage, or fluid leaks. Any abnormalities should be reported promptly, and necessary repairs should be performed by qualified personnel.

Ensure Proper Tire Inflation and Condition

Tires play a critical role in maintaining forklift stability and traction. Operators should regularly inspect tires for proper inflation, tread wear, and damage. Underinflated or worn tires can affect stability and manoeuvrability, increasing the risk of accidents. Employers should establish tire maintenance protocols and replace worn or damaged tires promptly.

What Is The Appropriate Operator Training and Awareness For Forklift Usage?

Provide Comprehensive Forklift Training

Effective operator training is essential for promoting safe forklift operation and stability. Training programs should cover load handling techniques, operating precautions, hazard awareness, and emergency procedures. Operators should be trained to recognize stability-related risks and take appropriate measures to mitigate them.

Foster a Safety-Conscious Culture

Creating a workplace culture that prioritises safety encourages operators to adhere to stability precautions and report potential hazards promptly. Employers should promote open communication, provide ongoing safety training, and recognize and reward safe behaviours. Empowering operators to take ownership of safety fosters a collective commitment to maintaining forklift stability.

Maintaining forklift stability is a multifaceted endeavour that requires careful attention to load handling, operating practices, environmental conditions, equipment maintenance, and operator training. By implementing a range of precautions and best practices, employers can minimise the risk of stability- related incidents and create a safer working environment for all. From adhering to load capacity limits to driving at a controlled speed and conducting regular equipment inspections, every precaution contributes to safeguarding stability and preventing accidents. Remember, prioritising stability precautions is essential for protecting the well-being of operators, bystanders, and valuable assets in any workplace where forklifts are utilised.

For a comprehensive forklift driving course taught by experienced trainers contact EDB Training Services.